# Optimizing Geotextile Fabric Performance for Superior Applications

Geotextile fabrics have become an indispensable component in modern civil engineering and environmental projects. Their versatility and durability make them ideal for a wide range of applications, from road construction to erosion control. However, to truly harness the potential of geotextile fabrics, it is crucial to optimize their performance. This article delves into the best practices for ensuring that geotextile fabrics deliver superior results in various applications.

## Understanding Geotextile Fabric Types

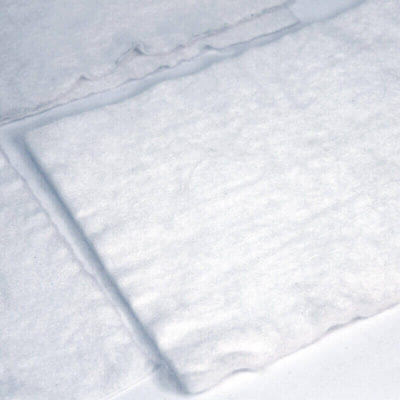

Before optimizing performance, it is essential to understand the different types of geotextile fabrics available. There are primarily two categories: woven and non-woven geotextiles. Woven geotextiles are made by interlacing fibers, providing high tensile strength and stability. Non-woven geotextiles, on the other hand, are manufactured by bonding fibers together, offering excellent filtration and drainage properties. Selecting the right type based on the specific application is the first step toward optimization.

## Key Factors Influencing Geotextile Performance

Several factors influence the performance of geotextile fabrics. These include material composition, fabric weight, permeability, and UV resistance. High-quality materials such as polypropylene and polyester are commonly used due to their durability and resistance to environmental factors. The weight of the fabric affects its strength and filtration capabilities, while permeability determines how well it can manage water flow. UV resistance is crucial for applications exposed to sunlight, as prolonged exposure can degrade the fabric over time.

## Best Practices for Installation

Proper installation is critical to maximizing the performance of geotextile fabrics. Ensuring that the fabric is laid out smoothly without wrinkles or folds can prevent stress points that may lead to tears. Overlapping seams adequately and securing the fabric with stakes or pins can enhance stability. Additionally, protecting the fabric from sharp objects during installation can prevent punctures that compromise its integrity.

## Maintenance and Longevity

To maintain the optimal performance of geotextile fabrics, regular inspections are necessary. Checking for signs of wear, such as tears or UV degradation, allows for timely repairs or replacements. In applications where the fabric is exposed to harsh conditions, using protective covers or coatings can extend its lifespan. Proper maintenance ensures that the geotextile fabric continues to perform effectively throughout its intended service life.

## Applications and Case Studies

Geotextile fabrics are used in a variety of applications, each with its unique requirements. In road construction, they provide stabilization and prevent soil mixing, leading to longer-lasting roads. In erosion control, they help retain soil while allowing water to pass through, reducing the risk of landslides. Case studies have shown that optimized geotextile fabrics can significantly enhance the performance and longevity of these projects, making them a cost-effective solution in the long run.

## Conclusion

Optimizing geotextile fabric performance is essential for achieving superior results in various applications. By understanding the different types of geotextiles, considering key performance factors, following best installation practices, and maintaining the fabric properly, engineers and project managers can ensure that their projects benefit from the full potential of geotextile fabrics. As the demand for sustainable and durable solutions grows, geotextile fabrics will continue to play a vital role in shaping the future of civil engineering and environmental protection.

Keyword: Geotextile fabric best